Optimal Uniform Paddy Dryers

Processed paddy carries too much moisture content levels ranging from 18–25%, storing it as-is risks spoilage, fungus, and weight loss – leading to quality issues and profit cuts. To store paddy safely, moisture must come down to 12–13%. And it has to happen evenly, without cracks or uneven grains.

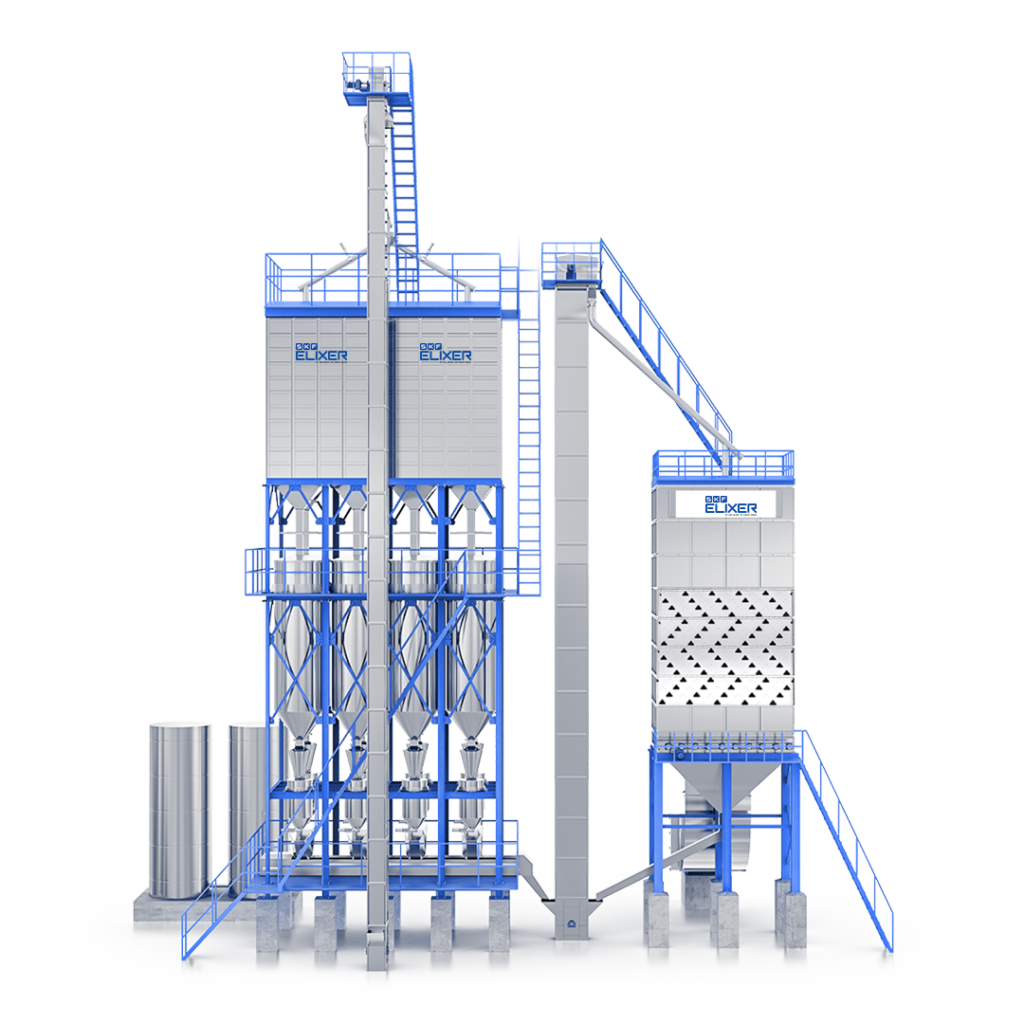

SKF’s Elixer’s Paddy Dryers is designed to reduce paddy moisture efficiently while keeping grain quality intact. Built using decades of process engineering experience, these dryers achieve uniform drying with minimal power consumption – saving operational costs while improving storage life and milling yield.

There are three models to fit your plant’s specific requirements:

Hot Air Furnace Dryer (Indirect Heating)

This dryer uses hot air technology via flue gas. Inside the furnace, husk and air combust to produce flue gas, which then passes through a heat exchanger. The hot air heat exchanger captures maximum heat from the flue gas, transferring it indirectly to the paddy. This ensures efficient drying without direct smoke contact. SKF Elixer was the first in India to develop this unique hot air drying technology, combining fuel efficiency with superior grain safety.

Steam Heat Exchange Dryer

This model uses steam from an existing boiler to heat air via a steam heat exchanger unit. The result is quick, precise temperature control, allowing faster drying cycles with exact settings for different paddy varieties. It’s ideal for plants with in-house boilers looking to integrate drying without additional fuel systems.

Cyclone Furnace Dryer (Direct Heating)

Built for large-scale, continuous drying, this dryer features multiple compartments with inverted “V” ports that guide paddy in a zigzag path. Wet paddy is lifted by elevators to the top boxes, where hot air from the heat exchanger is blown through plenums across the grain layers. The rotor mechanism at the bottom rotates at controlled speed, moving paddy downward evenly. Buckets then lift the paddy back up, creating a continuous top-to-bottom circulation. This perpendicular airflow and continuous grain rotation result in thorough moisture evaporation and uniform drying – batch after batch.

Applications

SKF’s Paddy Dryers are used by rice millers, parboiling units, and processing plants that need to store paddy for extended periods without risking fungus or spoilage. Whether you’re drying for immediate milling or seasonal storage, these dryers keep grain quality high while optimising fuel and power costs.

Advantages

Here’s why millers choose SKF’s Paddy Dryers:

- Enhanced heat transfer efficiency for faster drying

- Reuses husk as fuel, reducing operational costs

- Uniform drying without cracked or uneven grains

- Minimal power consumption saves running expenses

- Three models to match plant setup and fuel availability

- Built with durable, food-grade materials for long-term use

How It Works

Depending on the model, processed paddy is either heated indirectly via hot air or directly with controlled steam-based airflow. The dryers circulate grain continuously through elevators and rotors, ensuring each layer is exposed evenly to hot air currents. Moisture evaporates quickly and exits through controlled vents, leaving paddy at the safe 12–13% storage moisture range, ready for cooling and bagging.

With over 40 years of experience in parboiling, steaming, and drying plants, SKF Elixer builds dryers that aren’t just machines – they’re solutions engineered to protect grain quality, optimise fuel usage, and simplify your drying process from start to finish.

Get a free consultation today. Our team will assess your capacity needs, fuel systems, and layout to recommend the most cost-effective drying solution for your operations.