Modern Sewage Treatment Plant For Resort, Hotels & Hospitality Facilities

Most hotels and resorts are located near coastal regions, pristine landscapes, or other ecologically sensitive areas. These facilities generate significant amounts of sewage wastewater from kitchens, general cleaning, guest rooms, and bathrooms. If not managed responsibly, this wastewater can lead to environmental pollution, foul odours, health hazards, a negative guest experience, legal penalties, increased operational costs and a missed opportunity for water reuse and freshwater conservation.

Effective STP sewage management system is both critical and mandatory for the following reasons:

- The Government of India mandates the installation of sewage treatment plants (STPs) for residential, commercial, and hospitality projects that exceed a built-up area of 2,000 sq.m or generate more than 10 KLD of wastewater.

- Poorly managed sewage water from resorts can contaminate local water bodies and groundwater aquifers, affecting environmental and the ecological integrity of nearby recreational or coastal areas.

- Installing a modern sewage treatment plant can almost eliminate water running expense for non-portable applications that don’t necessarily require fresh ground water- such as toilet flushing, gardening, cleaning, car washing, cleaning floors, landscaping irrigation, and sprinklers.

SKF Elixer Offers Vulcan STP

The plug-and-play stainless-steel sewage treatment model costs you far less in the long term and consumes minimal electricity than any other conventional STP plant. It purifies and filters sewage wastewater into a reusable, non-portable water supply, reducing your water bills by a considerable percentage compared to the amount you spent on non-portable applications every month.

Vulcan sewage treatment plants are compatible with small, medium, and large hotels and resorts. They use mechanical and biological sewage treatments for the optimal wastewater filtration process. STP Vulcan has an integrated Air lift pump and energy-efficient diffusers that:

- Reduces the cost of maintenance due to Higher Bioreactor height and more oxygen transfer efficiency.

Reduced power consumption.

- Uniform air distribution.

Longer operational life with minimal sludge clogging.

- Sludge/biomass is aerated to create an odour/smell-free atmosphere.

- Doesn’t choke overtime. The STP Vulcan system is designed based on a normal settling tank.

Get The Best Price Quote

Click the form button below and fill in your details.

Once submitted, our team will promptly call or email you back with a best price offer.

STP Vulcan is equipped with a highly efficient biological treatment system known as the Advanced Attached Bio-reactor.

Inside the AABR bio-reactor, wastewater flows across advanced synthetic media that support the growth of beneficial microorganisms. These naturally occurring microorganisms consume organic matter pollutants such as BOD, COD, nitrogen, phosphorus) and reduces the total sludge load. This process happens on fixed surfaces rather than in free-floating sludge, the treatment remains stable and effective even under fluctuating loads. Keeps oxygen-rich aerobic conditions and drastically reduces harmful waste before the water moves to the next stage.

The fixed biofilm design allows for greater process stability, faster biomass development, minimal maintenance and odor-free which makes the STP Vulcan well-suited for resort and hotel environments where reliable continuous operation and compact design are most required. Following are the key benefits of AABR technology:

High durability – Built to last under continuous biological activity and environmental exposure.

UV resistant – Doesn’t crack or degrade when exposed to direct sunlight over time.

Non-clogging – Prevents blockage in pipelines and pumps, unlike conventional plastic media.

Easily washable – Simple to clean during maintenance without requiring chemical treatments.

Faster biomass growth – Promotes quicker microbial colonization for rapid wastewater treatment.

Reduced stabilisation time – Cuts down the time required for the system to reach peak biological efficiency.

Maintenance-friendly – Designed for smooth operation and easy access for cleaning or inspection.

Expandable capacity – Treatment capacity can be increased by simply adding more media, without needing structural changes.

Get The Best Price Quote

Click the form button below and fill in your details.

Once submitted, our team will promptly call or email you back with a best price offer.

Just In Time Investment

You only invest in treatment capacity as and when your sewage load increases. Various standardized sections are kept in stock which avoids heavy upfront investment, optimising your cash flow while ensuring compliance at every stage of growth.

Faster Delivery and Installation

Since most components are pre-engineered and stocked, the system can be delivered and ready for install within less than a month. By introducing biomass (active microorganisms) from other already-operating STP systems, the commissioning time is further reduced significantly. This helps the new system reach optimal performance quickly.

Less Footprint Area

Vulcan STP is designed to occupy minimal space, making it ideal for sites with area constraints. Its compact design allows easy integration into your existing infrastructure without the need for large dedicated spaces, saving valuable real estate for other operations.

Plant Capacity Augmentation

Plant capacity shall be augmented up-to 50% with the addition of advanced special media without any increase in foot print area and no major civil construction requirement.

Minimal Operator (Auto work)

This system operates with advanced automation, requiring little manual intervention. It reduces your dependency on skilled operators, ensuring hassle-free, reliable performance with minimal human error and operational oversight.

Made of Stainless Steel – Long Life of Units

Built entirely from high-grade stainless steel, Vulcan STP units are resistant to corrosion, chemical exposure, and harsh environmental conditions, ensuring a longer service life and reducing your replacement or refurbishment costs significantly.

Key benefits of Stainless Steel

No corrosion.

Easy to install.

Has resale value.

Aesthetically good

No painting or maintenance required.

Longer life (> 20 years).

Effective Nitrogen Treatment

The plant effectively removes nitrogen compounds from wastewater, preventing nutrient pollution in water bodies. This advanced treatment safeguards the environment from issues like algae blooms and supports compliance with stringent discharge standards.

No Foul Smell / Odour

The entire reactor operates under fully aerobic conditions with positive dissolved oxygen, eliminating foul smells commonly associated with sewage treatment plants. A top cover with a vent option further ensures a clean, odour-free environment around the plant.

Low Sludge Generation

The plant produces minimal sludge, reducing the frequency and cost of sludge handling, transport, and disposal. This not only lowers operational expenses but also simplifies overall plant maintenance and management.

Quick Maintenance (Low OPEX)

Designed for easy access and user-friendly servicing, Vulcan STP ensures quick maintenance with minimal downtime. Its low operational expenditure (OPEX) gives you cost-effective sewage treatment year after year.

Can Be Relocated If Required

Unlike conventional concrete-based STPs, Vulcan STP units can be relocated if needed. This flexibility is valuable during site expansion, redevelopment, or changes in facility layout, allowing you to adapt your treatment infrastructure with ease.

STP Vulcan is Compact & Modular Ideal for phased expansion of housing projects. Model capacity can be augmented with addition of AABR media.

Factory Assembled

Each unit is fully assembled and quality-tested at the factory before dispatch. This guarantees precise manufacturing standards, reduces on-site installation work, and ensures reliable performance from day one.

Plug and Play Plant Installation

The system is designed for plug-and-play installation, meaning it arrives ready to operate with minimal site work. You simply connect the inlet and outlet, power up the system, and it starts treating sewage immediately, saving you time, labour, and commissioning costs.

Get The Best Price Quote

Click the form button below and fill in your details.

Once submitted, our team will promptly call or email you back with a best price offer.

Vulcan STP Water Filtration Capacity

The raw untreated sewage water typically has a pH between 6.5 and 8, which Vulcan balances to a stable, neutral range of 7 to 8, making it safe for reuse.

The real difference is seen in pollution load. Incoming wastewater often carries high BOD levels between 250 to 300 mg/L, indicating heavy organic waste. Vulcan cuts this down to less than 10 mg/L, ensuring water is clean and oxygen-rich.

Similarly, COD levels, which measure total pollution, drop from 450–550 mg/L to under 50 mg/L, removing harmful contaminants.

Suspended solids, which make water turbid and unusable, reduce drastically from 150–250 mg/L down to just 10–20 mg/L, leaving water visibly clear.

Oils and grease, often floating in untreated sewage, are reduced to mere traces. STP Vulcan ensures that wastewater filters into clean, clear, odor-free, and ready for safe reuse or disposal.

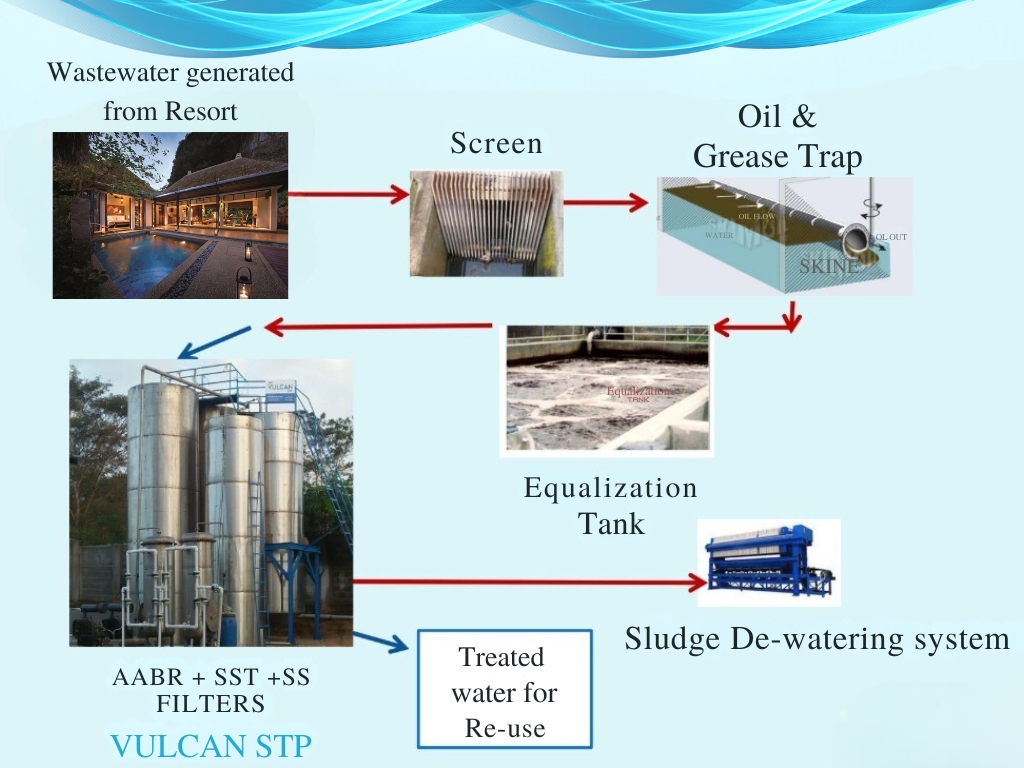

STP Water Treatment Process

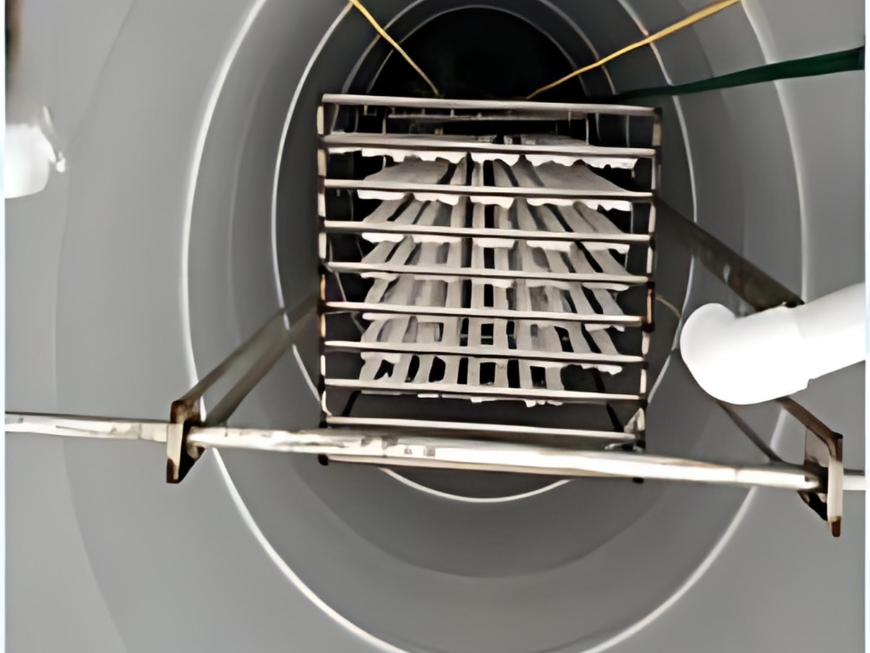

Screening (BSC)

Removes large debris and floating solids before wastewater enters treatment stages.

Oil & Grease Chamber (OGC)

Separates free-floating oil and grease to reduce load on biological treatment.

Equalisation Tank (EQT)

Homogenises flow and pollutant load for stable downstream treatment.

AABR Reactor (AABR)

Biological treatment where bacteria attached to synthetic media degrade organic pollutants.

Secondary Settling Tank (SST)

Settles out biological sludge after treatment.

Sludge Drying Bed (SDB)

Dries out dewatered sludge for easier disposal.

Clarified Water Tank (CWT)

Collects treated water after settling, ready for filtration.

Multi Grade Filter (MGF)

Filters out fine suspended solids.

Sand Filter (typically included in MGF or as separate)

Removes residual turbidity to improve water clarity.

Polishing Filter (PF)

Final filtration stage ensuring treated water is clear, safe, and odour-free

Get The Best Price Quote

Click the form button below and fill in your details.

Once submitted, our team will promptly call or email you back with a best price offer.

SKF Elixer India Private Limited Copyright © 2024 | All Rights Reserved