Transform your rice processing stages with state-of-the-art automation for enhanced efficiency, precision, and quality. Achieve higher yields and consistent product excellence while cutting down on labor and operational costs.

Automation cuts operational costs, boosts productivity beyond human limits, and minimizes errors for consistent, high-quality rice. It leads to efficiency, reliability, and product excellence at reduced costs.

At SKF, we deliver advanced Automation solutions tailored for rice processing. Our portfolio includes full plant Automation for integrated operations, hot water circulation Automation to maintain consistent temperatures, online cooker Automation for precise control over steaming phases, and drier Automation to manage moisture content and timing, thus optimizing drying.

These solutions are engineered to boost efficiency, ensure consistency, and elevate the quality of rice production.

Implementing Automation starts with a thorough process analysis to anticipate operational needs. We then develop a detailed flowchart that outlines each phase, laying the foundation for Automation design. The specification of digital and analog inputs/outputs is critical, equipping our systems for optimal performance.

The final step involves rigorous testing and live execution of the Automation logic to ensure seamless integration into existing plant operations, facilitating a smooth transition to Automated processes at every stage.

Our Automation processes are engineered to deliver precision, efficiency, and consistency, optimizing every aspect of rice production through advanced control systems.

Controls paddy discharge from storage to cooker.

Monitors cooker temperature for PLC feedback.

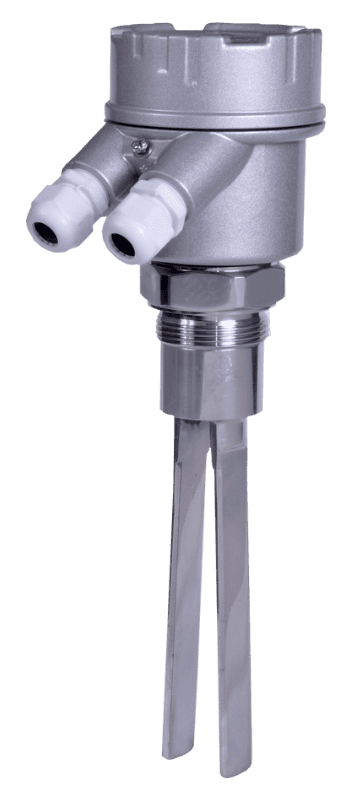

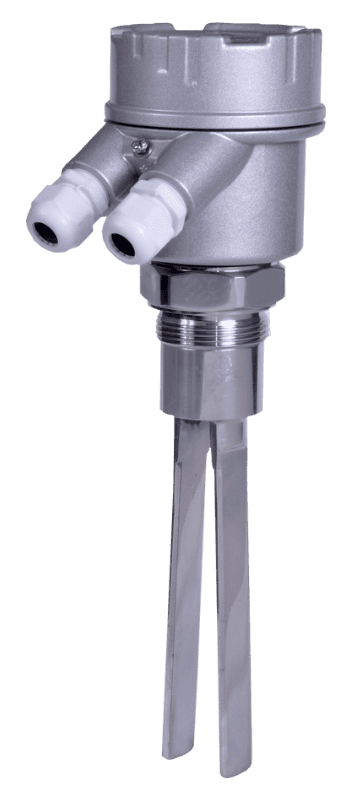

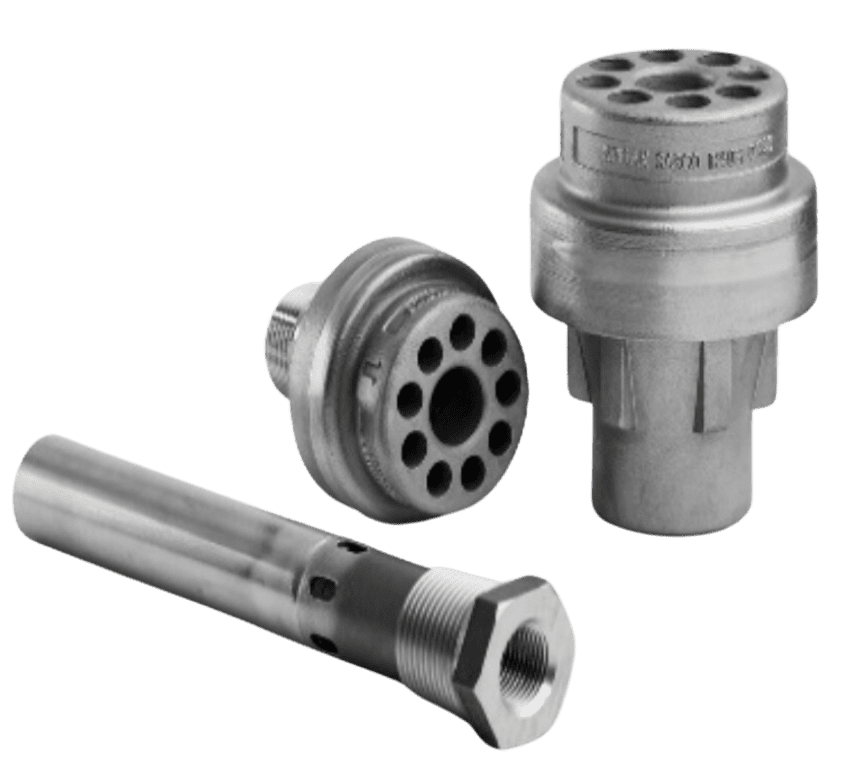

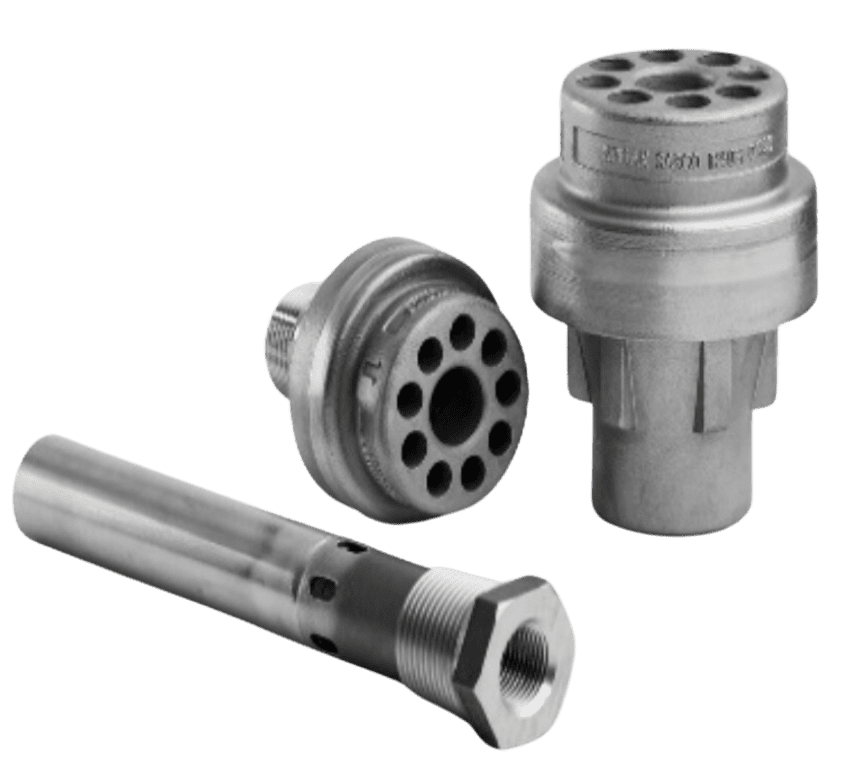

Manages paddy flow and prevents steam leakage.

Regulates bulk paddy and maintains system pressure.

For water circulation in soaking tanks.

Measures water temperature in tanks.

Maintains set temperature points.

Controls water flow for filling, discharging, and draining.

Introduces steam for temperature control.

Regulates steam for drying.

Monitors temperature for drying efficiency.

Accurately measures paddy moisture content.

Redirects product flow without dead spaces.

For temperature regulation across the plant.

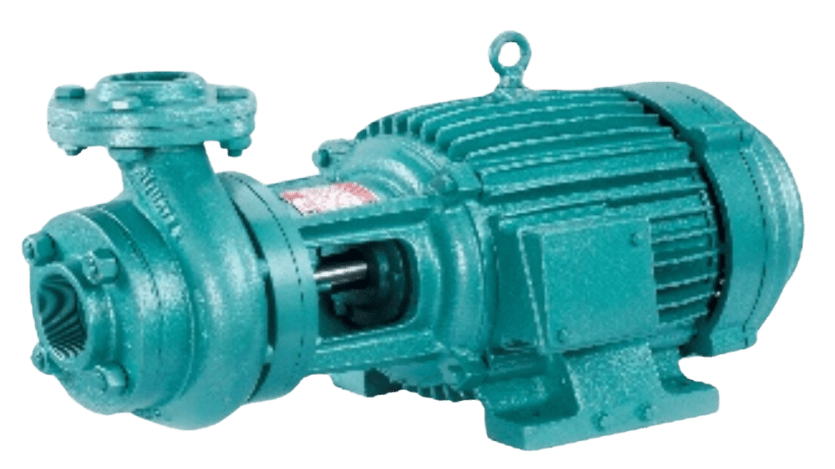

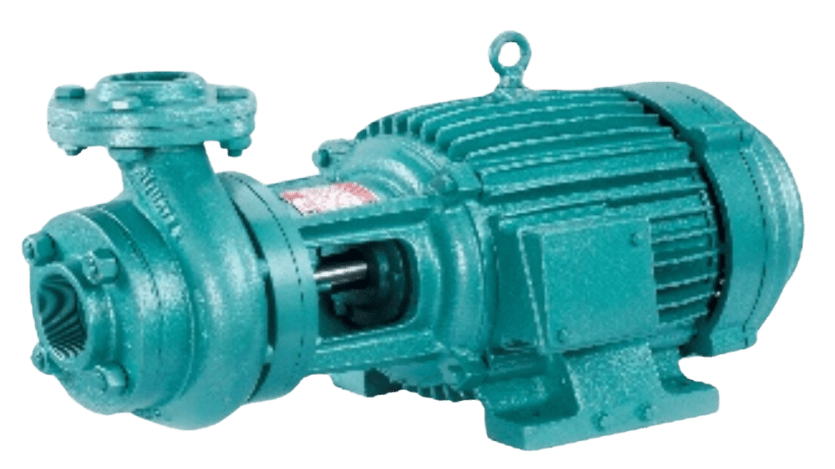

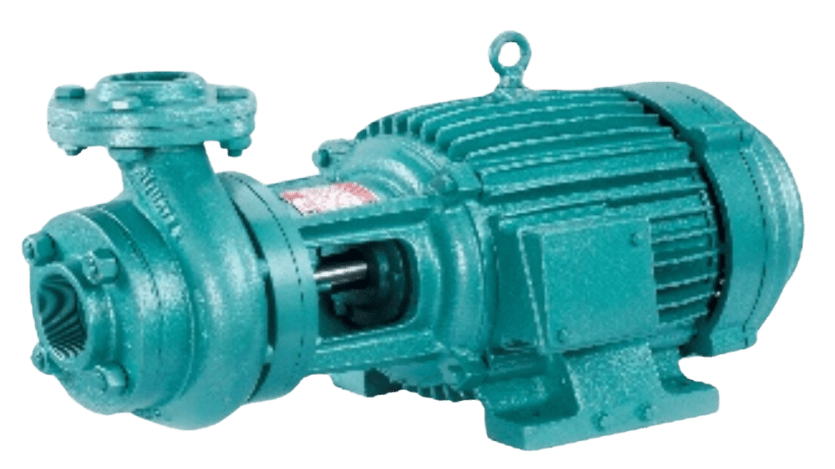

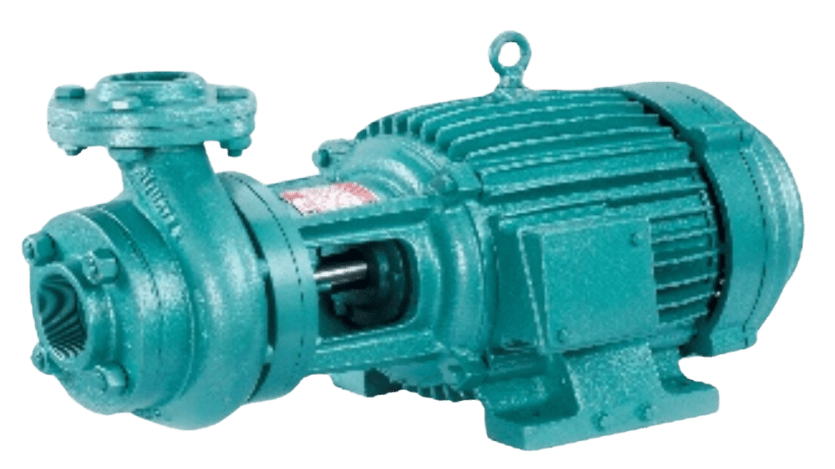

Ensures water circulation in various tanks.

Step into the future of agricultural technology along with water purification, and treatment solutions

SKF Elixer India Private Limited Copyright © 2024 | All Rights Reserved

SKF Elixer India Private Limited Copyright © 2024 | All Rights Reserved