Paddy processing plant is the very heart of a mill. The character and quality of rice is determined by the plant. SKF Elixer India Pvt. Ltd. is proud to present a single, online, all-in-one paddy processing plant that incorporates the technology of producing multiple types of parboiled rice as desired by customers. This plant can produce excellent quality steamed rice too.

SKF Elixer is now universally acknowledged by both millers and experts as the

Global Leader in Paddy Processing Technology.

SKF Elixer Grain Processing Products:

Benefits

- Fully Automated

- SCADA Enabled

- PLC Controlled for Optimum Steaming

- Perfect Color, Texture and Flavor

- Savings on Manpower

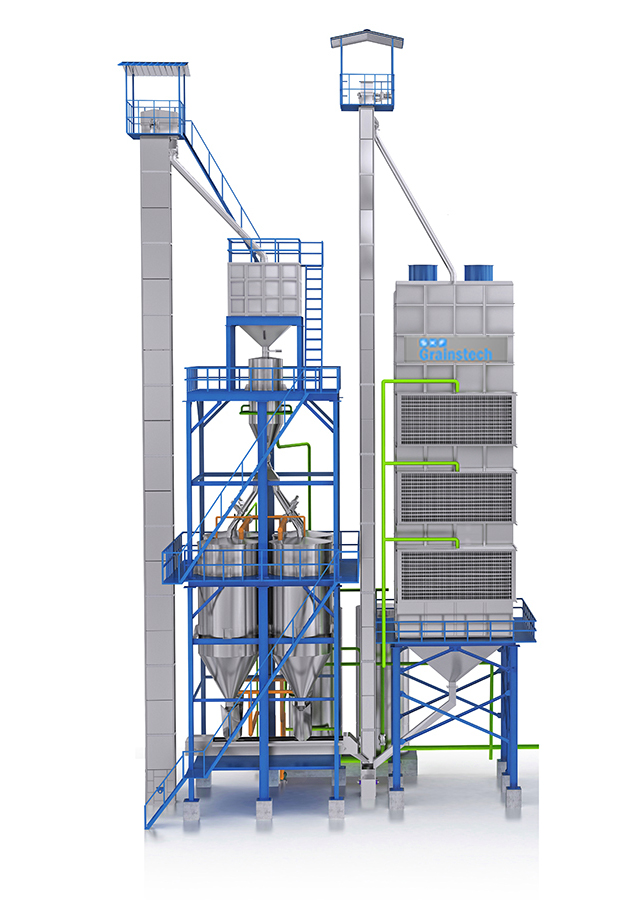

All-in-one Process

The all-in-one plants are equipped with high degree of automation and online customizations in order to produce variety of parboiled rice with the desired quantity and quality of carbohydrate, protein, vitamins and minerals. The advanced technology in these plants also ensures that the rice produced is of International standards in terms of color, texture and flavor. In addition to this, our products are built with maintenance free stainless-steel materials.

This equipment is most suitable to produce 3 types of export quality rice namely Basmati rice namely Creamy, Golden and White Sella.

Process includes pre-steaming the cleaned raw paddy for about 2-3 minutes followed by soaking via circulated water at just above the Gelatinization temperature till the desired moisture is achieved. Thereafter, the paddy is drained and transferred to steaming cooker for final steaming. The steamed paddy is then transferred to dryer for uniform drying, where the moisture content is reduced to 11-12% range. Processed paddy is finally transferred to tempering bin or silos.

Benefits

- Semi Automated

- PLC Controlled for Optimum Steaming

- Perfect Color, texture and flavor

- Minimal breakage during milling

- Optimum power consumption

Single/Double Boiled

This plant is designed to produce two types of parboiled rice namely Half Parboiled Rice (Single Steaming Process) and Full Parboiled Rice (Double Steaming Process).

Half Parboiled Rice (Single Steaming Process)

A section of parboiled rice eaters prefer translucent kernel with the rice having opaque (Dull White) portion at the centre and on sides. This type of rice cooks faster and has a soft texture.

Process includes soaking of raw paddy with circulated water at room temperature for 12 hours, depending on atmospheric conditions and the extent of preferred white core. Soaked Paddy is then drained completely and transferred to the cooker for final steaming. The steamed paddy is then sent to dryer for uniform drying, where the moisture content is reduced to 11-12% range. Processed paddy is finally transferred to tempering bin or silos.

Full Parboiled Rice (Double Steaming Process)

A large portion of the working-class population prefer to cook milled parboiled rice only once a day and thereafter consume it for 2 or 3 times. The left-over rice is kept in water overnight and consumed the next day. To achieve these characteristics, a separate type of parboiling technique is necessary. This Parboiled rice is distinguished by a translucent color which may not contain any opaque core (white) in the centre or on the sides of the rice kernel. This type of rice is cheaper than the single parboiled rice due to minimal breakage in milling process. The cooled rice will have a firm or sometimes mildly hard texture.

Process includes soaking the cleaned raw paddy with hot water. Soaked Paddy is then drained completely and transferred to cooker for final steaming and gelatinization. The steamed paddy is then sent to dryer for uniform drying, where the moisture content is reduced to 11-12% range. Processed paddy is finally transferred to tempering bin or silos.

Benefits

- Highly innovative curing process

- Produced rice resembles naturally aged rice

- Perfect color, texture and flavor

- Saves at least a year’s production time

Steam/Artificial accelerated Aged Rice Process

This plant is designed to produce Accelerated Aged rice using the Curing process. Certain section of consumers prefer the milled rice from aged paddy which when cooked will be firm in texture without exhibiting pastiness.

Process includes moving cleaned paddy to storage bin. If the moisture content of harvested paddy is 14% and above, it is dried to bring down the moisture content to 10-11% range. This raw paddy is filled into the steaming vessel where it is steamed and held till the rice acquires the desired uniform texture and color. The physical and chemical changes that occur at this stage gives the paddy an appearance of Aged rice. This paddy is then transferred to the dryer, where the moisture is reduced to 11-12% range. Processed paddy is finally transferred to tempering bin or silos.

Classic Model

For those who prefer traditional methods, SKF provides the Classic paddy processing plant where-in all process steps must be controlled Manually.

This demands highly skilled operators to control temperature, soaking intervals, drying at various temperatures, and the like.

INDIRECT HEATING

DIRECT HEATING

Benefits

- Enhanced heat transfer efficiency

- Reuse of husk

- Uniform drying

- Minimal power consumption

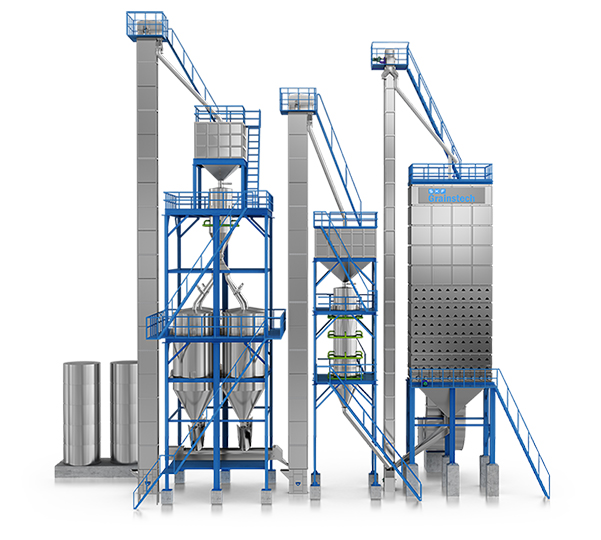

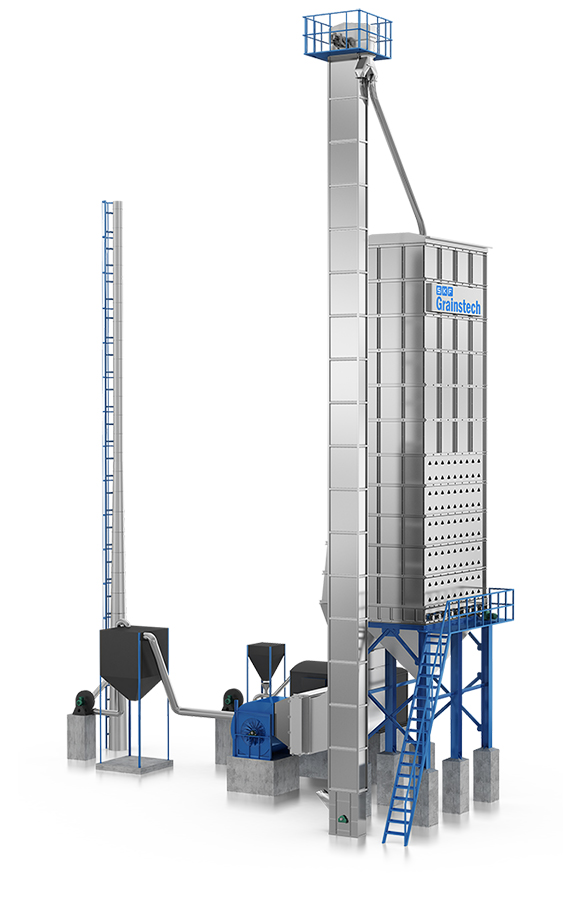

Dryer Models

Freshly harvested paddy consists of 18-25% of moisture which is unsafe for storage. The optimal moisture for storage is 12% to 13% which is effectively achieved by SKF’s Harvest Dryers.

There are 3 state-of-the-art Harvest Dryer models namely Hot Air Furnace Dryer, Cyclone Furnace Dryer and Steam Heat Exchange Dryer.

Indirect Heating

This dryer utilizes Hot air technology via flue gas. The hot air emanating from the Furnace (where husk and air are used for combustion resulting in flue gas) is made to pass through a heat exchanger. Hot air heat exchanger utilizes maximum heat from the flue gas, which increases the heat transfer efficiency. This heat exchanger provides an indirect heat required to dry the paddy. SKF is the first in India to have developed this unique hot air technology.

Steam Heat Exchange Dryer

This dryer utilizes Steam from boiler / dryer to heat air via Steam Heat Exchanger unit. Temperature can be quickly and precisely established using this mechanism.

Direct Heating

This dryer comprises of several compartments with inverted “V” ports arranged in a manner to create a zigzag movement of the paddy. An elevator takes the wet paddy from the dumping pit and fills the boxes of the dryer. Hot air from the Steam Heat Exchanger is forcibly blown through a duct known as plenum. Due to the unique placement of the inverted “V” ports, the hot air moves from one row to another evaporating the moisture which finally escapes to the atmosphere. The rotor arrangement kept at the bottom of the vertical LSU dryer rotates at a pre-determined speed and moves the hot paddy from top to bottom of the dryer. When this paddy reaches the boot of the elevator, it is taken by the moving buckets of the elevator to the top box of the dryer. This way the paddy is continuously rotated from top to bottom and the hot air is passed perpendicular to the zigzag movement of the paddy. This results in complete evaporation of moisture and uniform drying of the paddy.

SKF designed paddy processing plants comes with various types of Automated mechanisms in areas that include Hot Water Automation, Dryer Automation and Online Cooker.

Hot Water Automation

SKF developed hot water automation system in 2012. Advantages of the system include:

- Soaking period time reduced by half

- Saving of manpower

- Time and temperature automatically controlled by PLC and HMI

- Retrofit into old plants to increase production capacity

Dryer Automation

Paddy drying is a crucial step in the entire workflow of paddy processing. SKF provides timer-based automation of this process to ensure maximized yield of optimum quality rice. Highlights include:

- Online monitoring of moisture enables consistent outcome time and again

- Minimal cracking / broken grains due to uniform reduction of moisture

- Ensures accurate moisture content levels required for milling

- Temperature and other parameters are controlled automatically thereby avoiding human error

- The rotor is driven by AC drive which enables variable speed settings required during loading, unloading and recirculation

- The fan is also driven by AC drive which enables variable air flow temperature settings which is key to achieve optimum results

- All parameters can be set through a single command by selecting the blend of paddy using recipe system in SCADA

- Historical trends for every batch of paddy is available (data archiving)

Online Cooker

SKF developed online cooker in 2012 which achieves Automated Gelatinization process through PLC controls. SKF has installed over 200 online cookers across India and globally. Salient features include:

- Continuous and Uniform steaming

- PLC and HMI controls ensure high degree of automation (both pre and final steaming)

- Suitable for all types of paddy